Why Choose FIBC Ssuper Sacks?

Flexible Intermediate Bulk Containers (FIBCs) Ssuper Sacks are strong, high-capacity bags specifically engineered for the safe and efficient storage and transport of a diverse array of dry, granular, or powdered materials. These bags are essential in industries that require reliable bulk handling solutions. Typical applications include:

-

Agricultural Products

-

Animal Feed

-

Chemicals

-

Construction Materials

-

Food Ingredients

-

Fertilisers

-

Grains & Seeds

-

Minerals

-

Plastic Pellets

-

Raw Materials

-

Recyclable Materials

-

Sand and Gravel

PRODUCT FEATURES

Ssangleong provides customised packaging solutions tailored to each client. Our Bags are durable, available in various sizes, offer Ultraviolet (UV) and moisture protection, and are easy to handle. They ensure product safety during transport and storage across multiple industries.

-

Material Composition

Made from various materials, mainly polypropylene, which affects suitability for different bulk materials and environments.

-

Durability & Strength

Engineered for loads of 500 to 2,000kg, ensuring secure storage and transportation while preserving bag integrity

-

Capacity & Size Variations

Available in various sizes and capacities, these bags offer flexible storage and transport for bulk goods as needed.

-

Customised Design

Customized with prints, liners, and vents to meet product needs, improving efficiency and safety during handling and use.

-

Static Electricity Management

Designed with features to manage static electricity, Types A to D suit varying static risks from non-conductive to conductive materials.

-

Safety Standards

Each bag type adheres to safety standards, including limits on handling flammable materials and grounding requirements in specific environments.

TYPE OF FIBC SSUPER SACKS

Selecting the appropriate FIBC Super Sack is essential for protecting materials and ensuring compliance with industry safety standards. Different types provide specialized material properties and features designed to safely control static electricity.

Type A

CONSTRUCTION: Woven polypropylene.

CHARACTERISTICS: Lightweight, strong, UV and moisture resistant.

USAGE: Bulk storage of dry, non-hazardous materials like sand, grains and aggregates.

SAFETY GUIDELINES: Do not exceed weight limits; store dry.

PROHIBITED USE: Not for hazardous goods or liquids.

Type B

CONSTRUCTION: Made from insulating materials with low breakdown voltage.

CHARACTERISTICS: Prevents sparks but does not dissipate static electricity.

USAGE: For dry, flammable powders where no flammable gases or solvents are present.

SAFETY GUIDELINES: Avoid use where flammable vapours or gases are present.

PROHIBITED USE: Not for environments with explosive atmospheres.

Type C

CONSTRUCTION: Conductive woven fabrics with grounding features.

CHARACTERISTICS: Dissipates static to prevent ignition.

USAGE: High risk flammable or explosive powders.

SAFETY GUIDELINES: Ensure proper grounding during filling and emptying. Inspect grounding components before use.

PROHIBITED USE: Never use without verified grounding.

Type D

CONSTRUCTION: Made from static dissipative fabrics that safely discharge static electricity into the atmosphere without grounding. Dust containment depends on design features.

CHARACTERISTICS: For handling static-generating materials in explosive or flammable environments, without grounding. Dust proofing varies by coatings or liners.

USAGE: Fine powders and explosion-risk materials.

SAFETY GUIDELINES: Keep sealed and dry. Follow hazardous material procedures

PROHIBITED USE: Not for corrosive chemicals unless specifically rated.

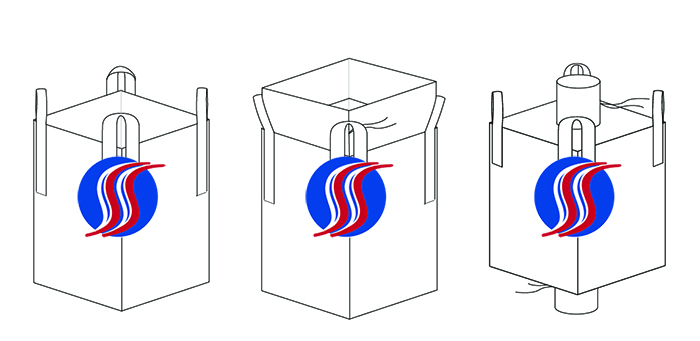

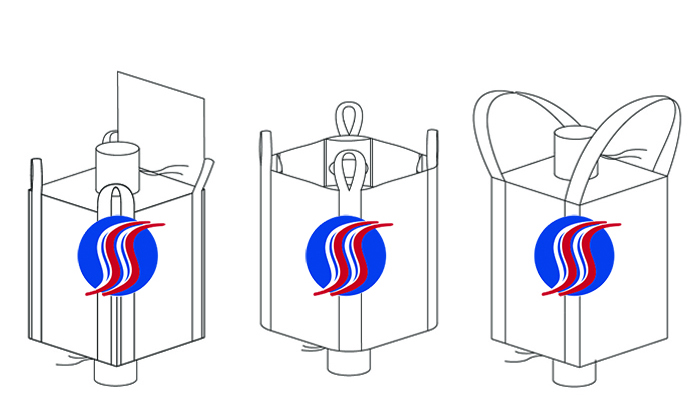

FILLING & DISCHARGE

Top Open

Top Open

Top Duffle

Top Duffle

Top Spout

Top Spout

Bottom Flat

Bottom Spout

Bottom Spout with Flap

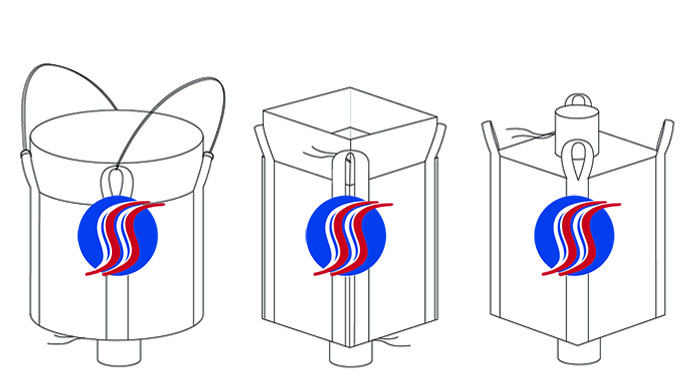

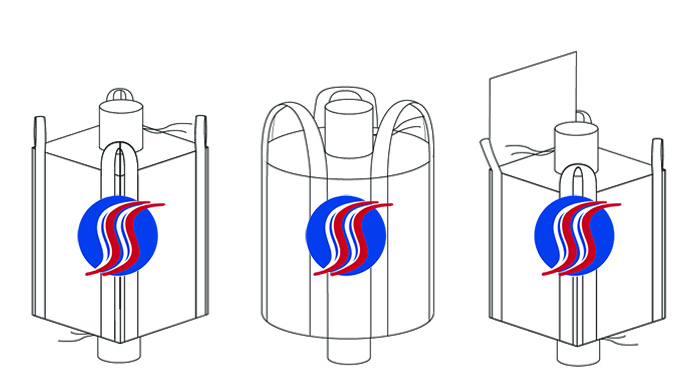

BODY CONSTRUCTION

4 Panels

4 Panels

Circular

Circular

Baffle

Baffle

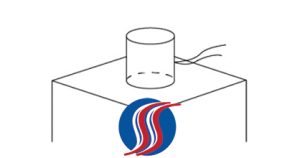

FIBC INNER LINER

An inner liner in an FIBC Ssuper Sack provides a protective barrier that prevents moisture, contamination, and leakage. This added layer is essential for maintaining product quality, particularly for fine powders, moisture sensitive materials, or products that must remain clean. Liners are often required to meet specific standards, such as antistatic or food grade regulations. By acting as a barrier, the liner prevents leaks or sifting, ensuring that the contents remain safe and intact during storage and transport.

Product Specification

Fabric

Dimension

Lifting Belts

Liner Materials

Liner Shape

Liner Attachments

Liner Features

Coating

Safe Working Load

Safety Factor

Document Pouch

Printing

100% Virgin, Recycled Grade, Antistatic, Conductive

Customisable Length x Width x Height

2 Loops, 4 Loops, Cross Corner, Side Seam, Stevedore

Polyethene (PE), Polypropylene (PP), EVOH, Aluminium Foil

Form Fit, Tube, Gusset, Baffle

Loose, Tabbed, Sewn In

Antistatic, Conductive, Food Grade

Ultravoilet (UV) Resistant, Lamination

From 500kg to 2,000kg

3:1, 5:1, 6:1, 8:1

21cm x 29.7cm (A4), 14cm × 21cm (A5), Fully Customisable

Up to 4 Colours

A detailed maker’s drawing for customer approval before production to ensure requirements are met.

A material sewn into bag corners to maintain the shape, steady the load, and utilize space efficiently.

The height of the bulk bag, measured from the top seam to the bottom seam.

An extra piece of fabric located near the lifting straps to prevent movement or increase the bag’s strength.

A 5:1 safety ratio means the bag has been tested to withstand loads up to five times its SWL without failing, but it should only be used up to its SWL during actual use.

Inspect the bags for damage before use, never overload them, and always use proper lifting equipment. Follow the safety instructions on the label attached to each bulk bag. Check the regulatory requirements for your product: hazardous materials require UN-certified bags, food products need FDA-compliant bags, and many industries follow ISO standards for quality and safety.

Yes, our bags are 100% polypropylene and fully recyclable. To join our FIBC recycling program, inspect used bags for contaminants and contact our team to arrange pickup or drop-off.

Ex-stock bags are available for same day collection or delivery if ordered before Singapore Time 12pm. Custom-made bags usually take between 5 and 7 weeks, depending on the design.