Why Choose FIBC Ssuper Sacks?

Flexible Intermediate Bulk Containers (FIBCs) Ssuper Sacks are strong, high-capacity bags specifically engineered for the safe and efficient storage and transport of a diverse array of dry, granular, or powdered materials. These bags are essential in industries that require reliable bulk handling solutions. Typical applications include:

-

Agricultural Products

-

Animal Feed

-

Chemicals

-

Construction Materials

-

Food Ingredients

-

Fertilisers

-

Grains & Seeds

-

Minerals

-

Plastic Pellets

-

Raw Materials

-

Recyclable Materials

-

Sand and Gravel

Product Features

-

Material Composition

Made from different materials, mainly polypropylene, which influences their suitability for various types of bulk materials and environments.

-

Durability and Strength

Engineered to withstand heavy loads between 500 kg and 2,000 kg, ensuring safe material storage and transport without compromising bag integrity.

-

Capacity and Size Variations

Available in various capacities and sizes, these bags allow for flexibility in the storage and transportation of bulk goods depending on the specific needs of the application.

-

Customised Design

Customised with features like prints, liners, and vents to meet specific product characteristics and handling requirements, thereby enhancing efficiency and safety during use.

-

Static Electricity Management

Designed with different features to manage static electricity. Types A, B, C, and D cater to varying levels of static risk, from non-conductive to conductive materials.

-

Safety Standards

Each type has safety standards related to its use, such as limitations on handling flammable materials and requirements for grounding in specific environments.

Type of FIBC Ssuper Sacks

Selecting the appropriate FIBC Ssuper Sack is critical for safeguarding materials and maintaining compliance with industry safety standards. Each type offers specific material properties and features engineered to effectively manage static electricity.

Type A

Fabric Construction: Woven polypropylene

Characteristics: Lightweight, strong, UV and moisture resistant

Ideal Use: Bulk storage of dry, non-hazardous materials like sand, grains and aggregates.

Safe Use Guidelines: Verifty the load capacity, ensure the maximum weight is not exceeded, store bags in a dry location to prevent mold formation and material degradation.

Prohibited Use: Do not use these bags for transporting hazardous materials or liquids under any circumstances.

Type B

Fabric Construction: Treated woven fabric reduces static discharge.

Characteristics: Safe for environments where static electricity is a risk.

Ideal Use: Chemicals and materials needing static control such as some pharmaceuticals and powders.

Safe Use Guidelines: Ensure bags are grounded at all times in static sensitive environments. Follow the manufacturer's specification for load restrictions and safe handling.

Prohibited Use: Do not permit use of these bags with flammable materials unless expressly engineered for that purpose.

Type C

Fabric Construction: Conductive woven fabrics incoporating advanced grounding features.

Characteristics: Dissipates static to prevent ignition of flammable materials.

Ideal Use: High risk flammable or explosive powders.

Safe Use Guidelines: Secure grounding connections during both filliing and emptying. Inspect each bag before use, paying close attention to grounding components.

Prohibited Use: Do not use bags for materials that require electrostatic discharge control.

Type D

Fabric Construction: Made from antistatic or static dissipative materials, often with added layers for dust containment.

Characteristics: Fully dust proof and designed for safe handling of staticgenerating materials.

Ideal Use: For fine powders, hazardous chemicals and materials with an explosion risk.

Safe Use Guidelines: Ensure bags are sealed and stored to prevent exposure to moisture or dust. Follow all recommended handling procedures for hazardous materials.

Prohibited Use: Do use these bags for storing corrosive chemicals unless explicitly specified for such use.

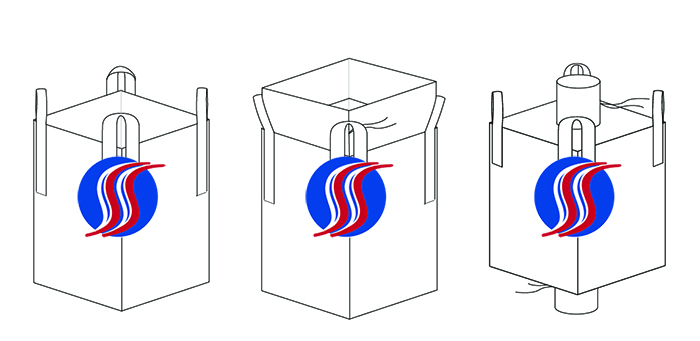

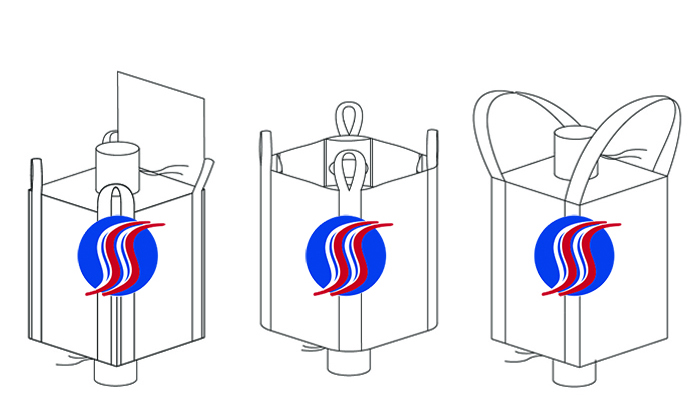

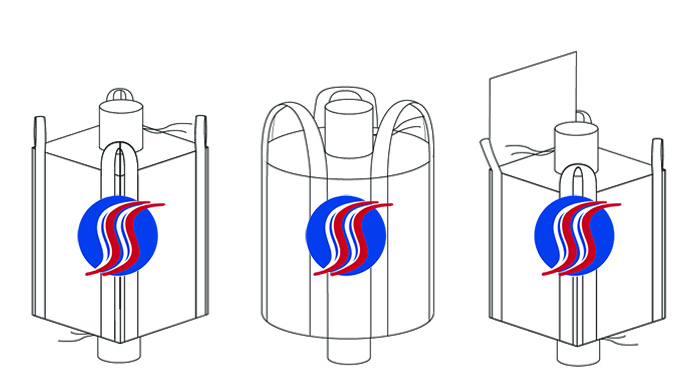

Filling and Discharge

FIBC bulk bags come in various top and bottom options to suit different filling and discharging needs.

Top Open

Top Open

Top Duffle

Top Duffle

Top Spout

Top Spout

Bottom Flat

Bottom Spout

Bottom Spout with Flap

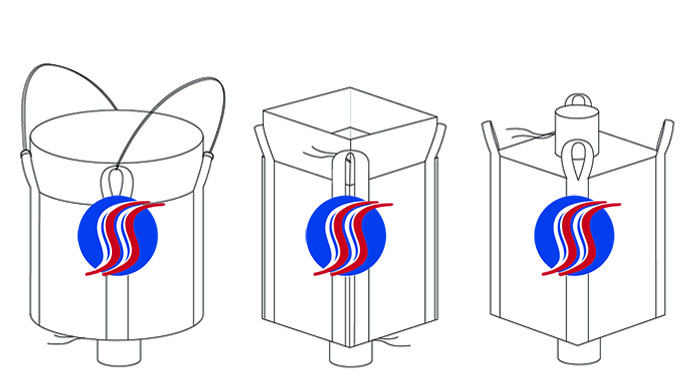

Body Construction

4 Panels

4 Panels

Circular

Circular

Baffle

Baffle

Product Specification

Fabric

Dimension

Lifting Belts

Liner Materials

Liner Shape

Liner Attachments

Liner Features

Coating

Safe Working Load

Safety Factor

Document Pouch

Printing

100% Virgin, Recycled Grade, Antistatic, Conductive

Customisable Length x Width x Height

2 Loops, 4 Loops, Cross Corner, Side Seam, Stevedore

Polyethylene (PE), Polypropylene (PP), Aluminum Foil, EVOH

Form Fit, Tube, Gusset, Baffle

Loose, Tabbed, Sewn In

Antistatic, Conductive, Food Grade

UV Resistant, Lamination

From 500kg to 2,000kg

3:1, 5:1, 6:1, 8:1

A4, A5, Fully Customisable

Up to 4 Colours

Type B FIBCs

Specifically designed to limit the build-up of static electricity. They feature a minimum breakdown voltage, making them safer for use in environments where there is a moderate risk of static discharge. However, they still should not be used for handling flammable materials.

INNER LINER

HDPE, LDPE, LLDPE and EVOH are some of our Inner Liners that help to prevent moisture and contamination in the Ssuper Sack. They are made with superior raw materials and have high quality standard of consistent thickness, seals and durability. The Inner Liner can be sewn-in, glued in place or inserted into the Ssuper Sack. A basic square base with four lifting loops sewn across the corners of the bag, is an economic construction for easy handling. The polypropylene fabric is designed to meet 5:1 and 6:1 safety factor. The standard Ssuper Sacks are excellent for a variety of application and custom designs are also available. Ssuper Sack Construction: Circular, Baffle, Four Panel, U-Panel Fabric Types: Type A - Normal, Type B - Anti-Static, Type C - Electrically Conductive, Type D - Static Dissipative Application Types: Multi-trip Sacks, Food Grade Sacks, Construction Sacks, Chemical Sacks, High temperature Sacks.

Type A Ssuper Sack

Type A Ssuper Sack are made from polypropylene and are suitable for the safe handling of dry bulk materials that do not pose a risk of static discharge.

Type B Ssuper Sack

Type A Ssuper Sack is specifically designed to limit the build-up of static electricity. They feature a minimum breakdown voltage, making them safer for use in environments where there is a moderate risk of static discharge. However, they still should not be used for handling flammable materials.

Type C Ssuper Sack

Type C Ssuper Sack is made from conductive materials and are equipped with conductive threads that help dissipate static electricity.

Ideal for transporting flammable products in environments where static charge can be a hazard. They must be grounded during use to ensure safety.

Type D Ssuper Sack

Type D Ssuper Sack is made from static dissipative materials and can safely be used in environments with a high risk of static discharge without the need for grounding. They provide a level of protection against static build-up while maintaining the flexibility and functionality of traditional FIBCs.

Twitter Analytics.

Data to Drive New Sales.

Transform your social media data into actionable insights. Our platform analyzes engagement patterns, audience demographics, and content performance to help you optimize your Twitter strategy and increase conversions.

FAQ

What is a bulk bag?

FIBCs Terminology

FAQ

What is a bulk bag?